Effective stock rotation is crucial for maintaining inventory visibility and accuracy while minimising obsolescence and waste from expiry dates. Warehouse and 3PL professionals often confront challenges such as inefficient FEFO implementation, traceability gaps in batch tracking, and compliance issues in segregation for perishable goods, leading to costly recalls and shrinkage. At Clarus WMS, we focus on pragmatic controls like GS1-based scanning, date and batch capture, and simple pick-rule configuration that help teams rotate stock reliably without over-engineering.

Traditional approaches to stock rotation rely on manual FIFO checks and sporadic inspections, which can take weeks to resolve ageing stock issues and achieve basic compliance. In contrast, a disciplined WMS setup enables FEFO-driven allocation, scan-to-verify steps, and faster exception handling when batches, dates or locations do not align.

The result of traditional methods:

- Delays in recall execution due to poor traceability and batch segregation

- Inefficiencies in FEFO stock rotation leading to expiry waste

- Lost revenue from non-compliance and inventory obsolescence

This article breaks down practical stock-rotation controls and shows where a modern WMS adds discipline without complexity. We weave in field insights from a warehousing professional to keep guidance grounded in day-to-day operations.

What is Stock Rotation and How Do I Optimise It?

Stock rotation means systematically moving inventory so older or nearer-expiry items are used first. Warehouses typically use FIFO for non-perishables and FEFO for shelf-life sensitive goods. FEFO is explicitly defined in public-health and pharma guidance as distributing or using the item with the earliest expiry date first, which translates neatly into WMS pick rules and slotting priorities (WHO GDP glossary).

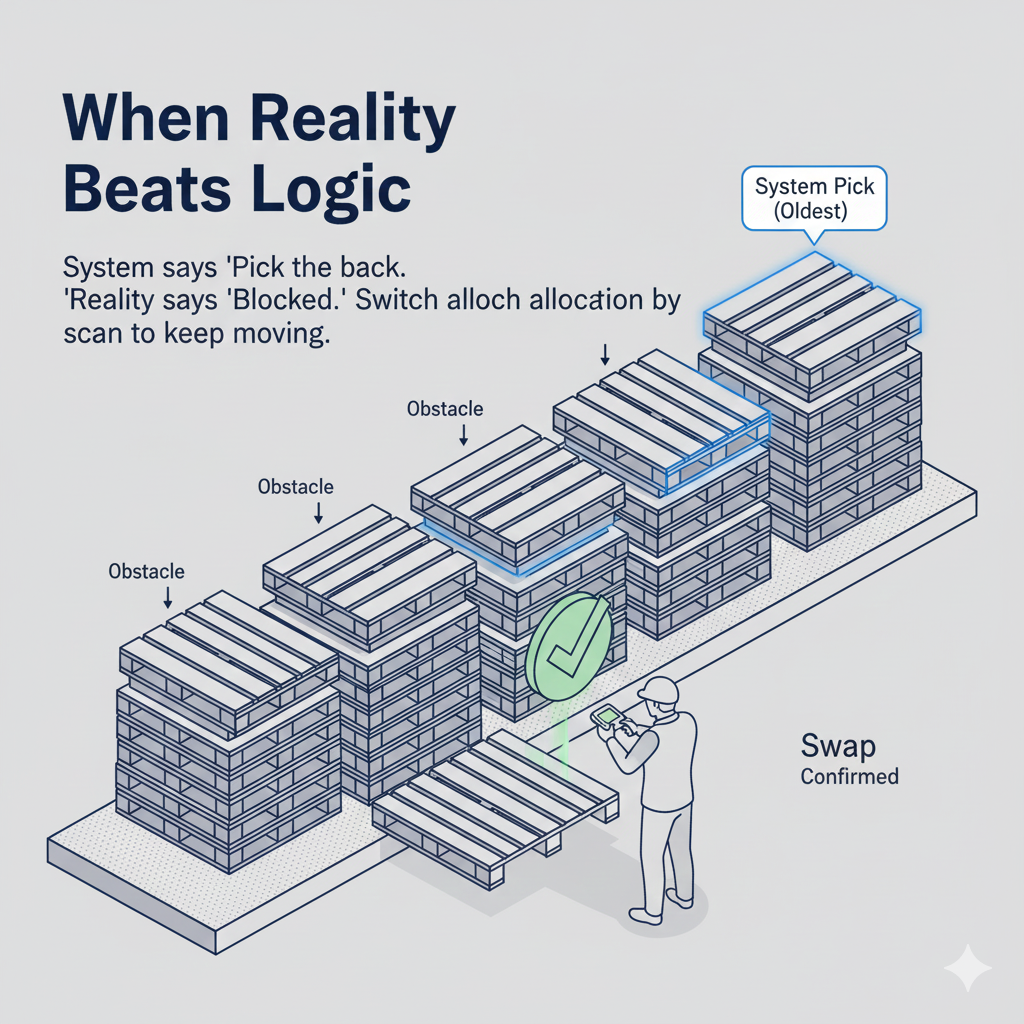

Expert insight: in Clarus WMS, FIFO is based on the stock-record creation date, while FEFO uses the item’s date attributes. A simple account-level “pick rule” determines allocation logic at order processing. If needed, teams can switch the allocated pallet by scan when the system’s oldest date is not physically accessible, which is common in bulk-stack areas.

Do I Need FEFO for My Warehouse Operations?

Use FEFO when products carry shelf-life controls or customer minimum-life requirements. FEFO reduces waste and helps compliance by prioritising items closest to expiry. UK food businesses are expected to manage hazards with documented procedures, so date-based rotation is often part of a HACCP-aligned approach (FSA HACCP overview, GOV.UK HACCP plan guide).

How Does Traceability Impact Shelf-Life Management?

Traceability links receipts, storage, picks and shipments to product identifiers, lots and dates, enabling rapid identification of at-risk stock. UK guidance emphasises maintaining traceability and being able to withdraw or recall food efficiently when required (FSA traceability and recall guidance). (Food Standards Agency)

With all required attributes captured at inbound, a WMS can instantly list what shipped, what remains in stock, and what is allocated but not yet despatched, then place holds to prevent further movement while compliant substitution occurs.

What Role Does GS1 Labelling Play in Batch Tracking?

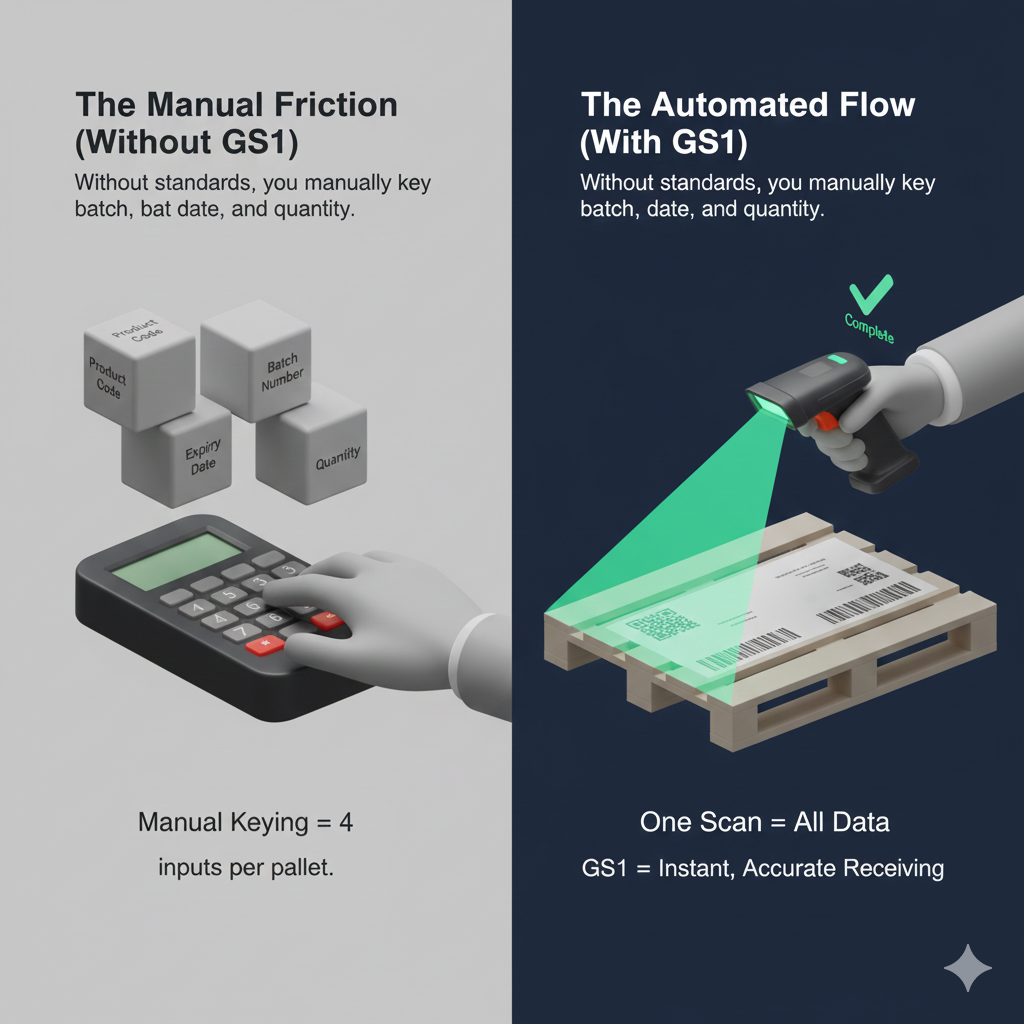

GS1 Application Identifiers encode key data into barcodes so a single scan can populate GTIN, lot, expiry and even SSCC pallet IDs. Relevant AIs include (01) GTIN, (10) lot/batch, (17) expiry, and (00) SSCC, among many others (GS1 AI directory, GS1 Support explainer).

Expert insight: “when suppliers ship with GS1-compliant labels, you avoid manual keying of product, batch, date and quantity. With an advance ship notice, inbound can drop to a single SSCC scan per pallet in high-volume flows.” Mathew Buttar, Head of Solutions.

Traditional Methods vs. Clarus WMS for Stock Rotation

Manual FIFO checklists and spreadsheets struggle under volume and SKU variety. In a WMS, FEFO rules allocate the right stock, scanners verify at pick and pack, and exceptions are managed by switching or reallocation where physically necessary. The aim is not complexity, it is repeatability, auditability, and fewer touches.

Why Teams Struggle with Stock Rotation

- Fragmented systems that hinder lot/date capture and audit trails

- Limited GS1 use, so operators must type batch and expiry repeatedly

- Manual rotation steps that increase waste and labour

- Weak zoning and grouping that risk cross-contamination or non-compliance

Practitioner note: group racking to keep sensitive categories separate, for example gluten-free areas segregated from standard goods, so system suggestions never send incompatible items to adjacent or over-under positions.

How Does Clarus WMS Handle Stock Rotation?

Clarus WMS combines date and lot capture on receipt, GS1 scanning, and account-level pick rules to allocate FIFO or FEFO consistently. Operationally, teams can switch by scan when the physically accessible pallet differs from the system’s first choice, while preserving batch and date controls. Where suppliers share data ahead of time, single-scan inbound against SSCC can accelerate receipts materially.

Real-Time Monitoring

Real-time lists of on-hand, allocated and shipped stock, with batch and date filters, shorten recall actions by letting teams hold at-risk lots immediately and substitute compliant stock on open orders. This aligns with UK guidance that stresses traceability and swift withdrawals or recalls (FSA recalls guidance).

Scalable Adaptation

When volumes spike, adding overflow space is practical if connectivity and labels are ready. Teams can stand up a new warehouse and begin receiving within minutes once locations and printers are configured, then lean on GS1 scanning to reduce keystrokes under pressure.

Full Visibility

Full visibility means end-to-end traceability, with GS1 data carried through each movement. GS1 notes that barcodes are scanned more than 10 billion times per day globally, reflecting how universal and reliable barcode workflows have become for everyday identification and capture (GS1 UK press note).

Ready to See It in Action?

Implementing disciplined stock rotation with a WMS transforms operations by reducing waste, protecting customers, and providing an audit trail that stands up to scrutiny. If you want the minimum viable controls to get FEFO right, start with GS1 labels, clean inbound capture, and simple pick rules, then iterate.

References

GS1 UK press note on 10bn scans/day

GS1 Application Identifiers directory, GS1

Which AIs should/must be used, GS1 Support

HACCP overview, Food Standards Agency

Make an HACCP food plan, GOV.UK