Mitchell Storage & Distribution (MSD) began life in the late 1990s as a courier company and has since grown into a sizeable logistics provider based in Coalville, Leicestershire.

Over time, MSD has expanded into pallet network distribution, cross docking, container de-vanning and import, warehousing and direct haulage across the UK. As a Palletforce member, it can now support customers well beyond its local area, servicing the whole of the UK and into Europe.

Despite this growth, MSD remains unmistakably a family business. The owners are still closely involved and that culture shapes how the team works. Business Development Manager Conor Stoneman explains that the ethos is to “treat [customers’] freight as our own and just make sure that they’re looked after.”

“We’re a big family-run company, and we like to bring that family ethos to our customers.”

– Conor Stoneman, Business Development Manager

This commitment to service also distinguishes MSD from more transactional providers. Many operators offer fixed, standardised services, but MSD aims to listen closely and then tailor its offer. Conor contrasts MSD with “one size fits all” logistics businesses, noting that MSD takes customer feedback on board and adapts its service around those needs.

That customer-centric approach created both opportunity and pressure. After moving into a larger site at the beginning of January the previous year, MSD saw freight volumes rise sharply. New customers were arriving, existing customers wanted additional services, and Palletforce volumes were increasing. MSD’s ambitions were growing too: it wanted to branch into more complex storage and handling solutions without losing control of costs or service quality.

However, the warehouse operation still relied on a bespoke, in-house system built by MSD’s logistics director years earlier. It had been “very good for what we were using [it] for at the time”, Conor recalls, but growth at the new site exposed its limitations.

Overcoming WMS Challenges Holding MSD Back

As volumes grew, the bespoke in-house system increasingly held MSD back. The first major issue was the amount of administration involved in everyday tasks. Stocks and Inventory Manager Luke Bodycot remembers how painful inbound booking used to be.

“Booking stock in was really hard. A container of forty pallets could take close to an hour.”

– Luke Bodycot, Stocks & Inventory Manager

Each pallet had to be added line by line, with the page refreshing every time. Even relatively simple receipts demanded a huge amount of manual input, leaving Luke struggling to keep up with day-to-day responsibilities.

The system was also “really clunky” and “time consuming” in general, Luke says. Trying to get everything updated at the end of the day so that records were live for customers was exhausting, and it made it difficult to perform the wider responsibilities of his role effectively.

On the operations side, the home-grown system struggled every time MSD tried to introduce a new service. Senior Operations Manager Dean Stevens recalls that the software worked, but every new customer requirement “stretched our resources, stretched our manpower” and forced staff into additional administrative work just to keep basic records up to date.

“Every time we tried to grow or add a service, it stretched our resources and our manpower.”

– Dean Stevens, Senior Operations Manager

Stock visibility and traceability were another major concern. Customers often needed to know how much inventory they had on hand or when a particular batch had shipped. Without a robust transaction history, MSD frequently had to rely on email trails or manual checks around the warehouse to answer these questions. If an error slipped into the record, it might not be spotted until a customer query forced an investigation.

Real-time visibility simply did not exist. A shipment might have arrived two days earlier, but until staff had updated spreadsheets and systems, customers could not see it. As Dean notes, “they’d have to ring us up [or send] emails… and then we’d have to go and check” because the system only reflected reality once someone had found time to update it.

Financially, MSD knew it was leaving money on the table. The business prides itself on bespoke services, such as reconfiguring imports from China into specific retail-ready case configurations. Under the old way of working, these complex jobs were often raised informally on the phone, passed verbally to the warehouse and not always recorded or invoiced properly.

Dean describes how ad hoc requests could consume wrap, labour and time without being charged. Without a central record of tasks performed or consumables used, it was hard to give customers accurate, transparent pricing and easy for internal costs to creep up unnoticed.

Inside the warehouse, generic locations and limited scanning meant operators might know a pallet was “in aisle K somewhere” but still have to search for it. Mispicks were more common and extra double-checks were needed to avoid sending the wrong pallet out, adding further labour and stress.

For Luke, the cumulative effect was demoralising.

“It just made me tired… it was really hard to do my job effectively.”

– Luke Bodycot, Stocks & Inventory Manager

It became clear that if MSD wanted to continue growing, expand its services and maintain its high-touch service model, it needed a warehouse management system designed for scale, transparency and flexibility. That realisation set the stage for the guide to enter the story.

Guiding MSD Toward WMS Transformation

When MSD began exploring the WMS market, it quickly became clear that many systems were not the right fit. Some were heavy, enterprise-scale platforms designed to control operations rigidly. Others required on-premise servers or offered little room for tailoring workflows. Dean, who had used around twenty different warehouse systems in his career, knew exactly what MSD needed and what it wanted to avoid.

He was not looking for “all the bells and whistles”, but for a platform that could handle core warehouse processes cleanly while offering the scope to grow and adapt as MSD’s services evolved. The system had to work for today’s needs, yet be flexible enough to support tomorrow’s strategies.

Cloud was essential. MSD wanted everyone from the managing director to the forklift driver to see real-time information, and it wanted customers to be able to log in and check their own stock levels without waiting for manual updates. An in-house server-based solution would not deliver the transparency or accessibility required.

Conor was already aware of Clarus WMS from LinkedIn and from conversations within the Palletforce network. Other depots that used Clarus had “left a very good impression” and actively recommended the system when MSD began asking about WMS options.

“Other Palletforce depots recommended Clarus to us that really got the ball rolling.”

Conor Stoneman, Business Development Manager

Clarus responded with a hands-on discovery process. The team visited MSD’s site, sat down with the leadership and operational teams, and asked detailed questions about how the business worked. Conor recalls that they “tailored it to our specific needs” and demonstrated that they understood how other Palletforce depots operated, which gave MSD confidence that Clarus could handle its mix of groupage, storage and bespoke services.

For Dean, the deciding factor was Clarus’s philosophy.

“A warehouse management system should support what you need it to be not make you conform to it.”

– Dean Stevens, Senior Operations Manager

Clarus WMS matched that view. The platform was flexible, could be configured without heavy custom coding and, crucially, the Clarus team was open to feedback. When Dean outlined complex unit-of-measure scenarios – such as pallets containing cases and single units that all needed to be managed and billed correctly – Clarus confirmed that not only could it handle this, it already had roadmap items scheduled to enhance those capabilities within a few months.

In Conor’s words, MSD values long-term partnerships, and Clarus clearly fit that category. The WMS would not only replace the ageing in-house system but also act as a strategic platform for growth, supporting MSD’s evolution into more value-added services and deeper network collaboration.

With the risks understood, the options evaluated and trust established, MSD chose Clarus WMS as its guide on the next stage of its journey.

Implementing the Solution: From Planning to Execution

Implementing a new WMS while settling into a new site could have been disruptive. Instead, MSD and Clarus treated the project as an opportunity to design better processes from the ground up. Clarus implementation specialist Mathew worked closely with Luke and Dean throughout onboarding, starting with a detailed review of how MSD currently operated and where pain points lay.

Luke recalls that Mathew was “really good and helpful”, taking the time to understand what MSD did, then showing how Clarus could prevent the issues they had been facing. Whenever questions arose, Mathew responded quickly, whether he was on site or supporting remotely.

“Every stage of the way he was there, telling us how to do things and how to adapt them.”

– Luke Bodycot, Stocks & Inventory Manager

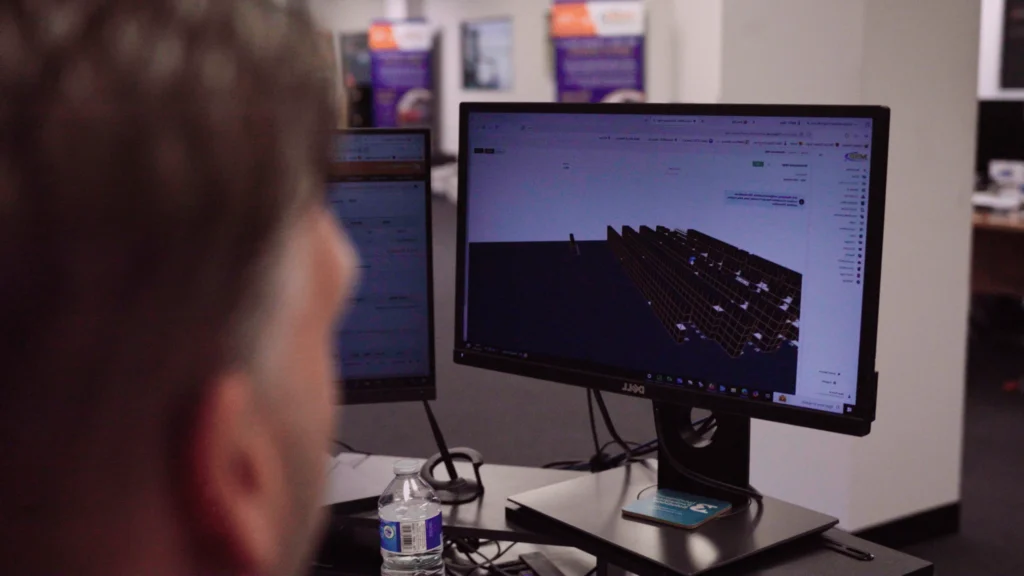

A major strand of the implementation involved defining and barcode-labelling every location in the new warehouse. Under Clarus WMS, all racking beams, bulk floor positions, inbound and outbound bays, quarantine areas and holding zones became scannable locations. This laid the foundation for Clarus’s 2D and 3D warehouse maps, giving MSD a live, visual view of capacity and stock placement.

Training focused on building confidence. Many staff had never used a full WMS or handheld scanners before, so MSD encouraged them to experiment. Dean describes telling the team to “just play with it… you can’t break anything.” Because Clarus has a single, clear menu structure, users quickly learned how to navigate without feeling overwhelmed by nested screens and obscure codes.

As Luke became more familiar with the system, he began to own it. He created step-by-step guides and a PowerPoint showing colleagues exactly how to receive stock, move pallets and generate pick lists. When a new team member joined, that person was able to book in his first receipt within five days, without direct supervision something that would have been unthinkable with the old system.

“Within a week the new starter was booking receipts flawlessly it shows how user-friendly Clarus is.”

– Dean Stevens, Senior Operations Manager

At the organisational level, MSD reshaped roles to reflect the new capabilities. Instead of a single warehouse manager juggling both staff management and stock administration, MSD appointed Luke as dedicated Stocks and Inventory Manager and put two team leaders in place for day-to-day running. Clarus WMS automated much of the previous paperwork, allowing Luke to focus on control, analysis and continuous improvement rather than manual data entry.

Meanwhile, Conor integrated Clarus into MSD’s commercial narrative. Prospective customers visiting the site now see the live 3D warehouse map on screen, then walk into the warehouse and find their pallets exactly where the system shows them. This has become a powerful demonstration of MSD’s commitment to transparency and control.

Results Achieved: WMS Success in Action

The combined effect of Clarus WMS and MSD’s process changes has been substantial, delivering measurable improvements in efficiency, accuracy, transparency and staff engagement.

One of the clearest metrics is the reduction in reactive customer communication. Because customers can now log in and see their stock and receipts in real time, they no longer need to call or email basic questions. Dean estimates he is “about 60% down on [customer contact] emails” asking about stock levels or costs, as customers already have the information they need.

“Emails and phone calls asking ‘how much stock have I got?’ have dropped by about 60%.”

– Dean Stevens, Senior Operations Manager

Inbound processing has been transformed. Tasks that once took Luke close to an hour per container are now completed significantly faster. Clarus allows him to book multiple pallets of the same SKU in one step and update locations via scanning rather than manual typing. Luke describes receipting as “so quick and easy” now, freeing time for other responsibilities.

Stock traceability has improved dramatically. Clarus records every transaction, making it straightforward to answer questions about when a pallet arrived, when it moved, and when it left. Luke particularly values the transaction history, which lets him show customers precisely what has happened to their stock, removing guesswork and preventing disputes.

“The transaction history is really great we can look back at anything and see exactly what happened.”

– Luke Bodycot, Stocks & Inventory Manager

Financial transparency has also improved. MSD can now configure each bespoke service – from re-boxing and kitting to cross docking and pallet wrapping as a distinct chargeable action in Clarus WMS. Every time a task is performed, it is recorded and appears on the customer’s invoice. Dean notes that this allows MSD to be “transparent and open” about pricing, explaining the labour, time and materials involved in each step.

Operational accuracy has risen while stress has fallen. Because every location is scannable and picks are validated against barcodes, mispicks are far less likely. Dean reports that during stock checks he is now “99.9% confident that everything in there is accurate, and everything that’s on Clarus is exactly where it’s supposed to be.”

The 2D and 3D warehouse maps have become integral to planning. Dean can now look at a screen and instantly assess whether there is capacity for an extra 500 pallets, rather than walking the warehouse or relying on rough estimates. If he spots a pallet from another customer in the middle of a block, he can click the location on the map and see exactly what is stored there.

For Luke personally, the difference is striking.

“It’s helped massively… it’s freed me up more time and actually got my love back for the job.”

– Luke Bodycot, Stocks & Inventory Manager

MSD has also been able to introduce new services. Clarus WMS underpins a cross-docking operation for Palletforce, where containers from Scotland and London meet at Coalville to swap freight before heading back out on the network. The system allows MSD to price this work accurately and track each movement, turning an operational capability into a reliable revenue stream.

Looking ahead, MSD is preparing to launch fulfilment services, including pick, pack and despatch. Thanks to Clarus, the team already knows how to create pick-face locations, assign min-max levels and manage replenishment. Clarus has confirmed support and is working with MSD to refine these processes, giving Dean the confidence to sell fulfilment to customers knowing the system will back it up.

Client Reflections and Lessons Learned

With some distance from the initial implementation, MSD sees its decision to adopt Clarus WMS as a pivotal moment in its evolution. The system has not replaced the company’s bespoke service ethos; it has made that ethos more sustainable.

By capturing every value-added activity and representing it clearly on invoices, MSD can be open with customers about pricing. Dean believes this transparency builds trust: when customers can see exactly what they are paying for, they know MSD is not hiding anything and has done the due diligence to price fairly.

The cultural impact inside the business has also been significant. Staff who were once weighed down by manual admin now spend more time on problem solving, planning and customer support. Luke has gone from feeling tired and constrained by the old system to being an enthusiastic super user of Clarus, training colleagues and exploring new ways to leverage the platform.

Crucially, MSD has learned that technology partnerships work best when values align. Clarus’s willingness to listen, adapt and build features requested by MSD mirrors the way MSD itself listens to its customers and tailors services to their needs. That shared mindset has turned the WMS provider into a genuine strategic partner rather than a distant software vendor.

Your Path to WMS Success

Mitchell Storage & Distribution’s journey shows how a growing logistics business can evolve from a home-grown system that once worked “well enough” to a modern, cloud-based WMS that actively drives growth, transparency and innovation. By acknowledging where the old tools were holding it back, MSD opened the door to a transformation that goes far beyond technology.

Today, MSD operates with faster and more accurate inbound processing, real-time visibility for customers, clearer billing for bespoke services, lower administrative load and a calmer, more engaged warehouse team. It has been able to introduce cross docking for the Palletforce network and is preparing to expand into full fulfilment, confident that Clarus WMS will support these moves.

If your organisation recognises similar challenges – manual booking, limited visibility, reactive customer communication or difficulty pricing bespoke services – MSD’s experience may resonate. The lesson from Coalville is not simply to buy a new system, but to seek a partner that will understand your operation, adapt to your needs and grow with you.

Clarus WMS has played that guiding role for Mitchell Storage & Distribution.

Discover how Clarus WMS can help your operation achieve similar results and begin your own journey to WMS success.