Mastering the goods-in process is essential for ensuring inventory accuracy and seamless inbound receiving, directly impacting overall throughput and compliance. Warehouse and 3PL professionals often face challenges such as delays in dock appointment scheduling, discrepancies in ASN matching, and inefficiencies in quality inspection, leading to overage, shortage, or damages issues that disrupt reconciliation. At Clarus WMS, we see this daily in operations handling multiple containers and ad hoc deliveries where a single bad day at the dock can erase margins for the week.

Traditional goods-in workflows relied on manual GRN verification and sporadic bookings, often taking days or even weeks to resolve OS&D reports and achieve putaway readiness. In contrast, a modern WMS approach integrates real-time automation, enabling efficient inbound receiving and cross-docking in hours, while optimising labour and boosting KPI performance. Best-in-class operations typically aim for dock-to-stock times of around 8 to 10 hours, while many 3PL operations still sit at 24 hours or more, so improvements in goods-in flow have a direct impact on service levels and storage costs. (ISM World)

The result of traditional methods:

- Delays in putaway due to manual ASN processing and poor dock scheduling

- Inefficiencies in inspection leading to unreported damages and quarantine bottlenecks

- Lost revenue from inventory inaccuracies and compliance failures in traceability

This article breaks down the failures of outdated methods in managing goods-in and explores how Clarus WMS rethinks the process with modern, cloud-based solutions for better visibility and regulatory audit trails. We also bring in practical experience from Clarus WMS implementation projects, including GS1-based pallet labelling, blind receipts, cross-docking, and quarantine workflows, to provide actionable insights for warehouse professionals.

What is Goods-In and How Do I Optimise It?

Goods-in refers to the inbound receiving process where shipments are booked, inspected, and reconciled into inventory, ensuring accuracy from dock to stock. This stage involves ASN matching, GRN verification, and quality checks to handle overage or shortage effectively. In 3PL centres dealing with high volumes, optimising goods-in means automating barcode scanning to enhance throughput and reduce errors in reconciliation.

When goods-in is poorly controlled, every downstream process, from picking to invoicing, inherits those errors. When it is optimised, it becomes the foundation for accurate inventory, reliable service levels, and credible KPIs.

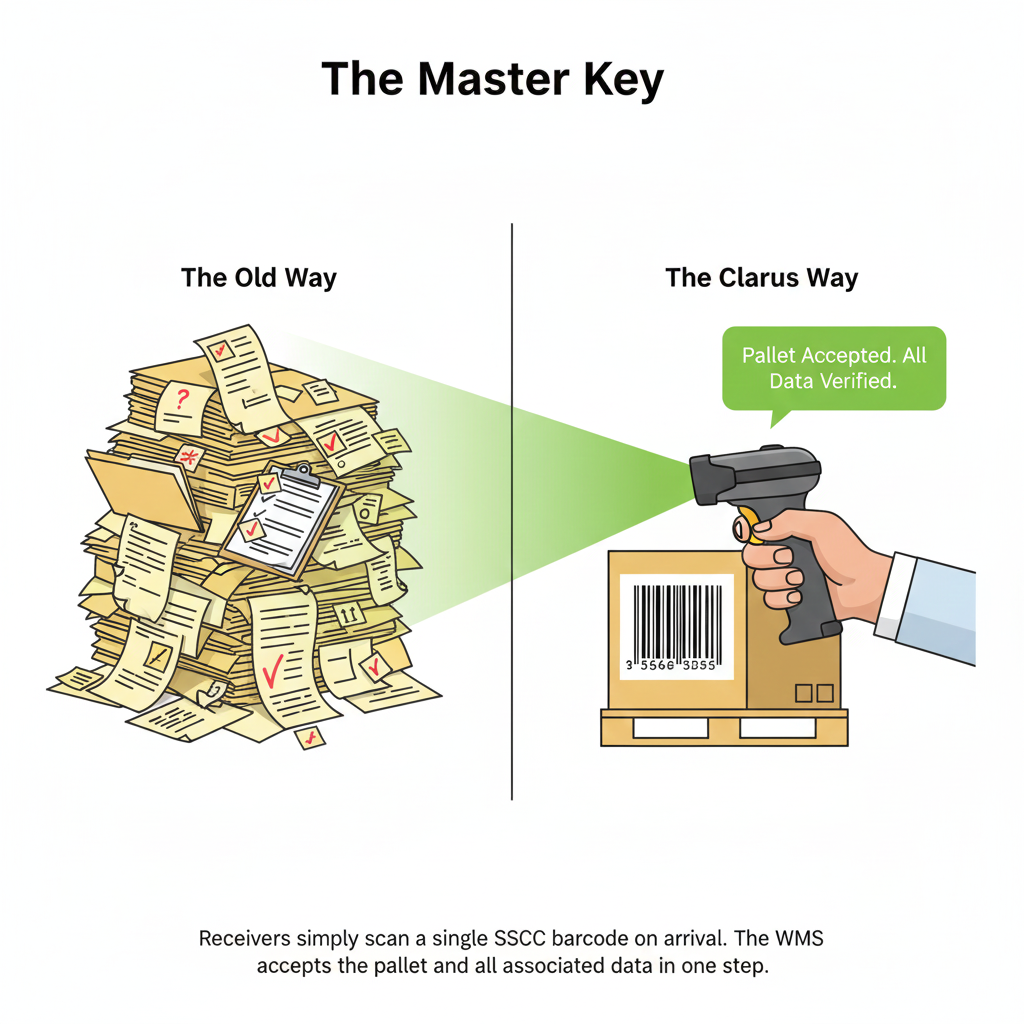

From an operational perspective, Clarus WMS consultants describe a “holy grail” flow where an ASN includes a GS1 SSCC pallet ID, batch, quantity, and product code for each line. In that scenario, receivers simply scan a single SSCC barcode on arrival and the WMS accepts the pallet and all associated data in one step, dramatically reducing handling time and keying errors.

Practical optimisation steps typically include:

- Using pre-receipts and ASNs for planned deliveries, with clear appointment times

- Enforcing three-way match (PO, ASN, GRN) where appropriate

- Standardising GS1 labels and barcode types across suppliers

- Using handheld flows that conditionally prompt for batch, best before date, or other attributes only when required by the account or product settings

- Monitoring dock-to-stock time, receiving accuracy, and OS&D rates on live dashboards

Integrating a cloud WMS like Clarus WMS allows for seamless licence-plate receiving and cross-docking, offering full visibility into inbound workflows. This links directly to benefits such as faster dock-to-stock time, fewer inventory variances, and stronger compliance reporting, all of which are highlighted in modern warehouse receiving best-practice guidance. (Descartes Finale)

Do I Need ASN for My Goods-In Operations?

Yes, Advance Shipping Notice (ASN) becomes essential as goods-in operations scale and inventory becomes more diverse. ASN provides advance details about each shipment, enabling efficient dock scheduling, pre-allocation of labour, and preparation of GRNs before a lorry arrives. In smaller, predictable operations, basic notifications may suffice, but once volumes increase or SKUs become more complex, the absence of ASNs typically shows up as queues at the dock and late putaway. (shipscience.com)

GS1 guidance highlights that electronic despatch advice messages, which function as ASNs, give warehouses accurate information about incoming loads, allowing them to plan receiving actions and streamline matching against orders. (gs1.org) Independent research also shows that ASNs can cut receiving costs by up to 40 percent because teams spend less time on manual checking and data entry. (Commport Communications)

Clarus WMS implementations commonly use two tiers of ASN-enabled receiving:

- Full ASN with SSCC: pallet-level SSCC IDs and item data are pre-loaded into a pre-receipt so operatives scan a single pallet barcode and the system accepts all associated quantities, batches, and dates in one go.

- Existing label receipt: where GS1 labels contain multiple barcodes (for example, article and quantity, batch, and SSCC), handheld flows allow the user to scan each in turn so data is captured without keying.

Implementing ASNs can reduce receiving time significantly in well-implemented warehouses. This not only streamlines putaway but also improves trust with customers through consistent traceability and more reliable KPI tracking.

How Does GRN Impact Inventory Accuracy?

Goods Received Note (GRN) directly enhances inventory accuracy by verifying shipments against purchase orders and ASNs, so teams can identify overage, shortage, or damages during goods-in rather than after the fact. It integrates with barcode scanning for real-time reconciliation, supporting compliance in quality inspection workflows and financial controls like three-way invoice matching.

Industry sources emphasise that a GRN is a critical document in procurement, because it confirms receipt of goods, records quantities and condition, and underpins accurate inventory and audit trails. (Cflow) When GRNs are digitised and tied to a WMS, they become part of a continuous data stream from dock to finance, reducing disputes with suppliers and reducing the risk of paying for goods that never actually arrived. (tofu.com)

In Clarus WMS, GRN data is not just a record; it drives operational status. Rules can automatically place receipts from certain suppliers or product groups directly on hold, pending external laboratory checks or veterinary certification, before the stock is made available. This approach combines inventory accuracy with controlled quarantine and clear audit trails.

What Role Does Barcode Play in Goods-In Efficiency?

Barcode scanning revolutionises goods-in efficiency by automating data capture at the dock, ensuring rapid ASN matching and GRN verification without manual errors. It supports licence-plate receiving for precise inventory tracking, facilitates cross-docking and quarantine decisions, and shortens OS&D investigation by linking each pallet to a clear digital history.

Warehouse technology guides note that manual data entry typically sees error rates around one in a few hundred keystrokes, while scanning reduces those errors to near zero and provides real-time stock visibility. (Balloon One) Barcode and RFID-based data capture at receiving is now standard in many best-practice frameworks for reducing carrying costs and speeding up putaway. (Balloon One)

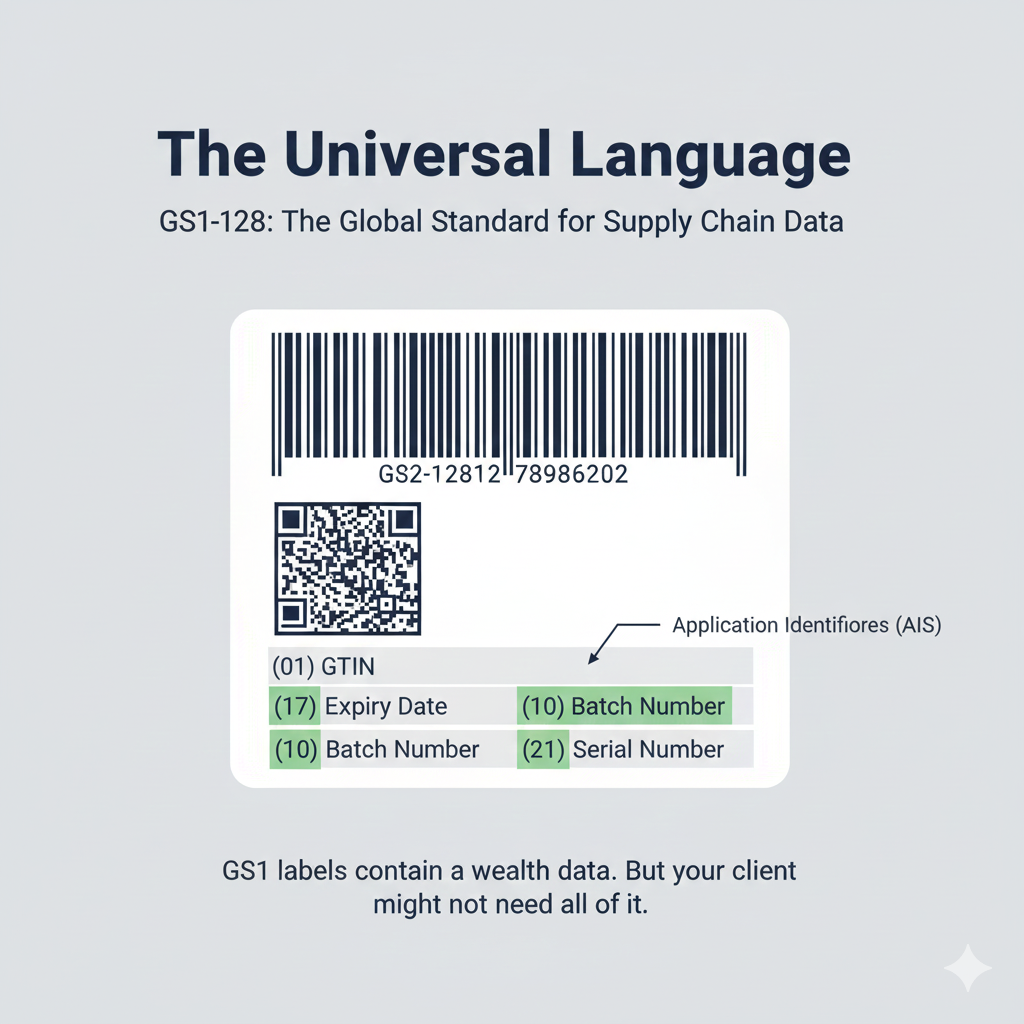

From a GS1 standpoint, a standard logistics label often includes multiple barcodes, for example:

- An article and quantity barcode

- A batch and date barcode

- An SSCC pallet ID barcode

Clarus WMS handheld flows allow customers to choose which application identifiers to capture based on account and product requirements, so the same generic component works for slightly different GS1 label layouts across multiple customers. This flexibility is crucial for 3PLs dealing with many trading partners.

Traditional Methods vs. Clarus WMS for Goods-In

Traditional methods often rely on paper-based GRN and manual ASN checks, leading to errors in reconciliation and delays in putaway that compromise inventory accuracy. These approaches lack real-time visibility, making OS&D reporting inconsistent and compliance labour-intensive. In many warehouses, receivers still key batch and date information by hand, which increases both cycle time and error risk. (packagex.io)

In contrast, Clarus WMS offers automated, cloud-based solutions that provide instant barcode integration for efficient receiving. Licence-plate receiving, GS1 label scanning, and configurable account and product flags control whether batch, best before date, or serial numbers are mandatory. Where legacy systems struggle with quarantine due to shortages or damages, Clarus workflows allow stock to be placed on hold automatically with reason codes that match the customer’s terminology, supporting transparent OS&D reporting through client portals.

A practical example from Clarus WMS experience involves glass-bottled beverages in fragile packaging. Without structured OS&D and hold reason codes, repeated breakages were treated as “just part of the job”. With a WMS capturing every damage event against specific SKUs and packaging types, operators can demonstrate that almost every touch creates a breakage, giving hard evidence for packaging redesign or charging rules.

Why Teams Struggle with Goods-In

Teams in warehouses and 3PLs often struggle with goods-in due to fragmented systems that hinder seamless inbound receiving and visibility.

Typical pain points include:

- Limited automation in ASN matching, causing gaps in GRN verification and audit trails

- Manual processes for inspection, increasing errors in OS&D and quarantine management

- Poor dock scheduling, risking spoilage and non-compliance with KPI standards

- Inadequate barcode integration, slowing down reconciliation in high-volume operations

Clarus WMS field experience shows that smaller 3PLs are especially exposed. It is common for unexpected loads or additional containers to arrive without warning, sometimes because high winds delayed ships and several days of containers land at once. When this happens, manual or spreadsheet-based receiving forces managers to trade off tipping containers, avoiding detention charges, completing picks, and finding floor space, often at the expense of accurate GRNs and safe operation.

As automation adoption grows, roughly a quarter of warehouses worldwide now use some form of automation, although only a minority have advanced systems. (meteorspace.com) This gap creates an opportunity, but also means many teams are still trying to solve modern inbound challenges with yesterday’s tools.

How Does Clarus WMS Handle Goods-In?

At Clarus WMS, we handle goods-in through a comprehensive cloud platform that ensures end-to-end visibility in inbound receiving. Our approach combines automation with real-time data, from ASN import to GRN confirmation, to support compliance and enhance inventory accuracy. This modern method addresses traditional pitfalls by prioritising speed and precision while still allowing for local SOPs around health and safety and customer-specific service levels.

Real-Time Monitoring

Real-time monitoring in Clarus WMS provides instant alerts for damages, shortages, and non-compliant pallets, ensuring traceability throughout inspection. It supports barcode integration for seamless cross-docking, and status changes are driven by explicit events such as “received”, “on hold with reason code”, or “released from quarantine”.

Health and safety expectations, such as never moving obviously broken pallets into racking, are usually handled through local SOPs. However, Clarus handheld flows can include checks, for example asking an operative to record pallet condition or broken pallet counts, so that compliance teams have data to support training and charging decisions.

Scalable Adaptation

Scalable adaptation allows the system to grow with operations, handling increased volumes without losing goods-in accuracy. Clarus WMS dashboards typically start with task-centric views, such as outstanding receipts, putaway tasks, and user-level completion rates, then evolve into customer-specific KPIs as operations mature.

This model mirrors best practice advice that stresses continuous monitoring of receiving metrics, such as dock-to-stock time and error rates, in order to identify bottlenecks and justify targeted investments in automation and labour. (hopstack.io)

Full Visibility

Full visibility encompasses end-to-end tracking from dock to putaway, with detailed audit trails for regulatory audits. This includes who received which pallet, what data was captured at the time (batch, date, condition), which reason code was applied for any hold, and how that stock later moved through the warehouse.

In warehousing, this level of traceability is not just a compliance requirement; it also underpins meaningful discussions with customers about damage rates, packaging quality, and inventory performance. External guidance on warehouse receiving strongly supports digitised records and audit-ready transaction histories as a way to improve both operational control and supplier relationships. (Descartes Finale)

Ready to See It in Action?

Implementing advanced goods-in processes with Clarus WMS can transform warehouse operations, reducing risks and enhancing efficiency. With a combination of ASN-led receiving, configurable GS1 label support, GRN-driven accuracy, and clear KPIs, teams can move from firefighting at the dock to predictable, auditable performance. Imagine achieving seamless compliance and real-time visibility without the traditional hassles of paper, spreadsheets, and manual chasing.

Contact Clarus WMS for a demo to explore how these principles could apply in your own operation.

References

- Clarus WMS, “Goods-In & Its Impact on Warehouse Performance”

- GS1, “Delivering Value in Shipping and Receiving” (PDF)

- GS1 UK, “Improving Supply Chain Efficiency – Getting Value from Standards Adoption”

- Commport, “Advanced Shipping Notice Made Simple: Your Quick Start Guide to ASN Success”

- TrueCommerce UK, “What Is ASN? Meaning, Uses and ASN Number Explained”

- Cflow, “Goods Received Note – What it is and Why is It Important in Procurement?”

- HighRadius, “What Is Goods Received Note (GRN): Importance & Best Practices”

- Finale Inventory, “Warehouse Receiving Process: Best Practices & Steps to Improve Efficiency”

- PackageX, “Master Warehouse Receiving Processes: A Guide to Optimization + Best Practices”

- Balloon One, “Precision in Receipting: How to Measure Receiving Efficiency”

- WarehouseWhisper, “Best Warehouse Barcode Scanners (2025 Guide)”

- ISM, “The Monthly Metric: Dock-to-Stock Cycle Time”

- APQC, “Dock-to-Stock Cycle Time in Hours for Supplier Deliveries”

- KPI Depot, “Dock-to-stock Cycle Time”

- Meteor Space, “Important Warehouse Automation Statistics in 2024”

- MHI / Locus Robotics, “The Collaborative Supply Chain: 2024 MHI Annual Industry Report” (PDF)