If you manage a warehouse or 3PL operation, you already know that warehouse mapping and slotting can either be your silent advantage or your daily headache. As order profiles fragment, SKUs explode and customers expect next-day delivery as standard, the old “rough sketch of the warehouse and tribal knowledge” approach to warehouse mapping simply can’t keep up.

In the UK alone, the warehousing sector has grown by around 61% since 2015 and now approaches 700 million sq ft of space, with 3PLs still the leading occupier group. (Logistics Matters) That expansion means more locations to maintain in your warehouse mapping, more decisions to make about slotting, and more pressure to squeeze labour efficiency from every pick route. Done well, warehouse mapping optimisation turns that complexity into clear, repeatable processes. Done badly, it shows up as congested aisles, missing pallets, emergency re-slotting and exhausted pick teams.

We see the same pattern again and again when we review warehouse mapping for new customers. Slotting rules exist on paper, but the live warehouse mapping in the WMS no longer matches reality. Locations have been reused ad-hoc, pick faces have crept closer to despatch “just for peak”, and nobody quite trusts the map when something goes wrong. That disconnect between warehouse mapping and real-world slotting is often the root cause of accuracy and productivity issues.

At Clarus WMS, we treat warehouse mapping and slotting optimisation as core infrastructure rather than a one-off project. The goal isn’t a beautiful static map—it’s a living model of your locations and slotting that drives walk sequence, travel time, replenishment and exception handling. In this article, we’ll answer the questions we hear most from warehouse and 3PL leaders about mapping and slotting, share what the data says, and show how we approach warehouse mapping optimisation in practice.

What is warehouse mapping and why does it matter?

Warehouse mapping is the digital representation of your physical space—every zone, aisle, bay, level and slot—that your WMS uses to store and retrieve stock. When warehouse mapping is done properly, the structure of your locations directly supports slotting decisions, pick routes and inventory visibility. When warehouse mapping is rushed or left to evolve organically, slotting rules become harder to enforce and every exception takes longer to resolve.

A robust warehouse mapping structure usually starts with a location code that breaks the warehouse into logical elements (for example, site, zone, aisle, column, row and slot). That warehouse mapping code is what your WMS uses to drive walk sequences, pick-path ordering and replenishment logic. If the underlying warehouse mapping is inconsistent—missing aisles, reused slots, non-standard codes—any slotting optimisation you try to layer on top will be fragile.

From a cost point of view, warehouse mapping matters because picking dominates labour. LIDD estimate that in a typical warehouse, picking represents roughly half of all labour, and about half of that time is simply travelling between locations. (LIDD) If warehouse mapping is messy and slotting is inefficient, you multiply that wasted walking across every shift. Clean warehouse mapping plus smart slotting optimisation, by contrast, means every extra metre walked has been deliberately traded for better ergonomics, batching or cube utilisation.

Warehouse mapping is also the backbone of traceability. In 3PL environments with multiple clients and strict SLAs, regulators don’t care what your racks look like; they care that your system can prove where each pallet has been. Accurate warehouse mapping and disciplined slotting ensure that every scan links a storage unit to a real, auditable location—even when you’re relying on temporary overspill or external canopies.

How does slotting optimisation cut travel time and labour cost?

Slotting optimisation is the process of deciding where each SKU should live in your warehouse mapping to minimise travel, protect fragile goods and meet service commitments. While warehouse mapping defines the “canvas”, slotting is how you use that canvas day to day. Data-driven slotting can have a dramatic impact: several studies suggest smart slotting can cut picker travel time by up to 30%, especially in large warehouses with high SKU counts. (bizbloqs.com)

Good slotting optimisation usually blends three ingredients with your warehouse mapping:

- Velocity: fast-moving SKUs closer to despatch and at ergonomic pick heights

- Affinity: items often ordered together slotted near each other in the warehouse mapping

- Constraints: weight, hazard class, temperature, FEFO/FIFO and client-specific slotting rules

Because picking is such a large share of warehouse labour, even small slotting gains pay back quickly. LIDD note that picking accounts for around 50% of warehouse labour, with roughly half of that time spent walking. (LIDD) Reducing travel through better slotting optimisation doesn’t just save minutes; it directly improves picks per hour and reduces fatigue, which in turn reduces mis-picks and errors.

Modern slotting optimisation goes beyond one-off ABC analysis based on annual demand. Many 3PLs now refresh slotting monthly or even weekly, using 26–52 weeks of order history to feed algorithms that recommend new pick faces and replenishment points while respecting the underlying warehouse mapping. External guidance supports this shift: practitioners at LIDD argue that effective slotting balances movement data with ergonomics and capacity limits, rather than chasing pure travel-time minimisation. (LIDD)

In our own work, we often start by reviewing the slotting “north star” against the existing warehouse mapping: which SKUs should be in golden zones, which actually are, and which are stranded in slow-moving corners. By iterating slotting changes in waves—perhaps one aisle or client at a time—you protect day-to-day operations while steadily improving your warehouse mapping and slotting alignment.

What data do you actually need for warehouse mapping?

A common concern is that warehouse mapping and slotting optimisation require perfect CAD drawings before you can begin. In reality, most WMS platforms (including Clarus WMS) build the operational map from structured location master data rather than from a digital twin alone. For practical warehouse mapping, you typically need three layers of data:

- Location structure for warehouse mapping

- Site, building and zone identifiers

- Aisle, bay/column, level/row and slot codes

- Location types (pick face, bulk, staging, returns, quarantine, etc.)

- Site, building and zone identifiers

- Physical attributes to support slotting optimisation

- Maximum pallet dimensions and weight per location

- Temperature or hazard constraints per zone

- Whether a location is suitable for case-pick, each-pick or full pallet

- Maximum pallet dimensions and weight per location

- Product master and movement data for slotting

- Dimensions and weight per SKU

- Velocity, order line frequency and unit of measure

- Special rules: FEFO, batch/lot, serialised items, client-specific constraints

- Dimensions and weight per SKU

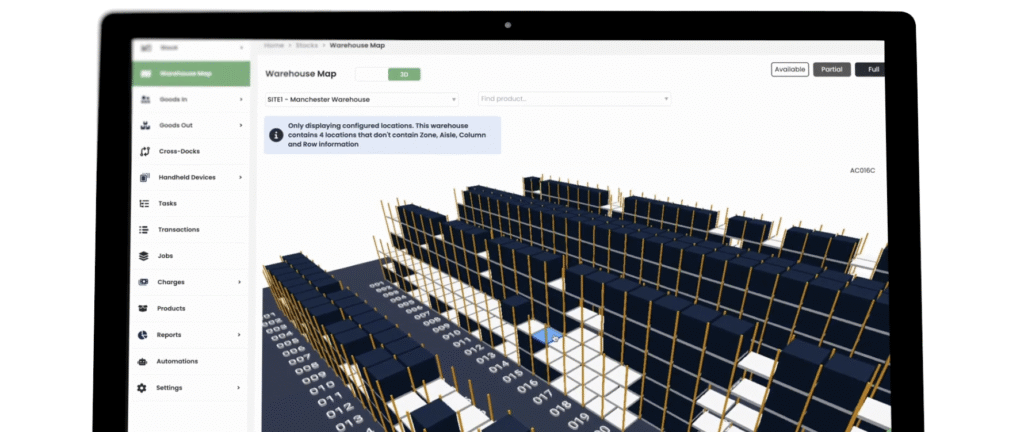

Once this data exists, the warehouse mapping can be auto-generated by the WMS into a grid view so supervisors can see where each rack and slot sits relative to despatch or goods-in. In Clarus WMS, for example, the map is driven by your location codes and walk sequence, not vice versa, so you can focus on getting the warehouse mapping logic right before worrying about fine visual tweaks.

The most overlooked data point in warehouse mapping is walk sequence. Pick routes in many systems are ordered by a simple sequence field attached to each location in the mapping—“location 1” might be the furthest point in the back corner, while “location 10,000” is next to goods-out, or vice versa. Deciding whether your slotting should flow towards despatch or away from it can shave significant time off every route, especially in high-density pick modules.

Our recommendation is to treat location and product master data as a joint responsibility between operations and IT, not as a one-off WMS project. Warehouse mapping and slotting only stay healthy if someone owns data standards, audits location usage and cleans up orphaned slots after reconfigurations or client changes.

How do digital twins and heat maps improve warehouse mapping optimisation?

Digital twins and heat maps are often talked about as futuristic tools, but their value is very concrete when you’re tackling warehouse mapping optimisation. A digital twin is simply a virtual replica of your warehouse operations that you can experiment with safely. McKinsey describe digital twins as a way to “design, simulate, and test new warehouse operations” virtually before changing the real facility, helping companies improve efficiency by around 20–25% without disrupting live operations. (McKinsey & Company)

For warehouse mapping, a digital twin lets you test new aisle directions, additional pick faces or alternate slotting strategies using real order data. You can ask questions like:

- What if we move our top 50 SKUs to a new fast-pick zone in the mapping?

- How does cross-aisle travel change if we reverse walk sequence in two aisles?

- What happens to replenishment load if we halve pick-face capacities?

Vendors such as Optioryx report that digital-twin-driven routing can reduce walking distances on the warehouse floor by 20–50%, by generating optimised routes and highlighting congestion in the virtual model before you change your warehouse mapping. (blog.optioryx.com) Even if you don’t implement a full 3D model, the principle holds: simulate first, then alter your mapping and slotting rules.

Heat maps, meanwhile, are a simpler but powerful way to visualise where activity actually happens within your warehouse mapping. LIDD note that “heat maps can provide valuable insights into order pick paths, highlighting the most efficient routes and identifying areas prone to bottlenecks.” (LIDD) With even a basic BI tool, you can use scan events (or RTLS/RFID reads if available) to overlay movement density onto your warehouse mapping and spot:

- Hotspots where slotting is causing cross-traffic

- Cold zones where warehouse mapping and slotting are underutilised

- Aisles where travel time is consistently longer than expected

In our experience, the most pragmatic approach is to use your WMS as the single source of truth for warehouse mapping and slotting rules, then export movement data to a BI platform to build heat maps. That keeps governance with the WMS while still giving operations teams visual tools to challenge and refine their warehouse mapping optimisation decisions.

When should 3PLs revisit their mapping and slotting strategy?

For 3PLs, warehouse mapping and slotting are never “finished”. Client portfolios evolve, product mixes swing with seasonality, and new SLAs demand different levels of responsiveness. We usually recommend that 3PLs build a cadence for warehouse mapping optimisation instead of waiting for problems to surface.

At a minimum, a 3PL should review warehouse mapping and slotting annually, with a deeper review whenever one of three triggers occurs:

- New client onboarding

A new client with a very different order profile or packaging standard should almost always prompt a fresh look at zone design, slotting rules and walk sequences in the warehouse mapping. Without that, 3PLs often end up bolting new pick faces onto old mapping structures, creating permanent inefficiencies. - Sustained order growth or SKU proliferation

UKWA and Savills highlight how online retail and 3PL growth have transformed UK warehousing, with total warehouse space up around 61% since 2015 and online retailer occupancy rising over 800%. (Logistics Matters) When throughput expands like this, slotting schemes designed for lower volumes tend to break down, resulting in congestion and emergency overflow that undermines the original warehouse mapping logic. - Service or safety issues

Rising mis-pick rates, frequent stock-not-found events, or near-miss incidents around certain aisles are all warning signs that your warehouse mapping and slotting no longer match reality. In those cases, a targeted re-mapping of affected zones is often more effective than broad process training.

Because 3PLs trade so heavily on responsiveness and transparency, we see warehouse mapping optimisation as a core part of client governance. Simple tools like before-and-after travel-time analysis per route, or heat maps per client zone, can be powerful evidence when you’re justifying changes to slotting or storage pricing. Over time, a disciplined approach to mapping and slotting becomes a genuine commercial differentiator in the 3PL market.

Traditional mapping struggles vs modern WMS approaches

Where older mapping and slotting processes go wrong

Many warehouses we encounter still rely on static drawings, spreadsheets and long-serving supervisors to maintain their warehouse mapping. In theory, these drawings describe the same warehouse mapping as the WMS; in practice, they diverge steadily as slotting changes accumulate. Static maps rarely reflect temporary racking, outside canopies or floor-stacked overflow, which leads to inconsistent location use and unreliable slotting.

Traditional mapping and slotting projects also tend to be one-off. A team spends months configuring bin codes, defining zones and importing CAD-inspired layouts. Once the project goes live, change control weakens, and warehouse mapping adjustments are made on the fly to fix urgent problems: a new fast-pick location for a top SKU here, an improvised quarantine area there. Over time, this erodes both mapping integrity and slotting effectiveness.

On top of that, many legacy WMS deployments treat digital twins and heat maps as “nice to have” analytics, rather than embedded tools for warehouse mapping optimisation. Yet external research suggests that simulated redesign using digital twins can lift warehouse efficiency by 20–25% before any physical change is made. (McKinsey & Company) Without these tools, teams are often reluctant to touch established warehouse mapping and slotting rules, even when they know they’re suboptimal.

How we handle mapping and slotting in Clarus WMS

We take a different approach. In Clarus WMS, the warehouse map is generated automatically from your location master data—zone, aisle, column, row and slot—rather than being a static drawing you have to maintain by hand. That makes it faster to set up warehouse mapping initially, but more importantly, it makes ongoing slotting changes safer because the visual map always reflects the underlying data.

Our philosophy is to keep the digital map opinionated but honest. Clarus WMS gives a clear visual representation of where each pallet should be according to the warehouse mapping and slotting rules, even if the physical racking isn’t perfectly linear. Supervisors can still “walk the floor”, but they’re supported by live mapping, real-time transaction data and walk sequence-driven pick lists instead of relying solely on memory. That balance of system-driven warehouse mapping and human judgement tends to land well with both old-school operations managers and data-driven planners.

Ready to improve your warehouse mapping and slotting?

If your team no longer fully trusts the warehouse map, or if slotting discussions always end with “we’ll just pick it manually for now”, it’s a sign that your warehouse mapping optimisation is overdue. You don’t need a full robotics programme or a 3D digital twin to make meaningful progress; starting with consistent location codes, clear walk sequences and refreshed slotting rules can unlock surprisingly quick wins.

At Clarus WMS, we typically begin with a focused mapping and slotting review: one site, one client, or even one problem aisle. From there, we help you iteratively clean up your warehouse mapping, align slotting with real demand patterns and build the data foundation for future tools like heat maps and digital-twin simulations. If you’d like to see how Clarus WMS handles warehouse mapping and slotting in practice, our team can walk through live examples and discuss what “good” could look like in your operation.

References

- Marc Menard, “Strategies for Effective Warehouse Slotting,” LIDD, 4 April 2024

- Chris Hagle, “Heat Maps in Warehouse Operations: Maximizing Warehouse Productivity with Heat Maps,” LIDD, 24 January 2024

- Ashutosh Dekhne and Vedang Singh, “Improving Warehouse Operations—Digitally,” McKinsey & Company, February 2020

- “Simplifying Decision Making for Warehouses with Digital Twin,” Optioryx Blog, 2025

- “Slotting Optimization in 2025,” Bizbloqs Logistics Management, 2025

- “UKWA Report Marks Long Term Growth of Warehousing Sector,” Logistics Matters summarising Savills/UKWA research, 2 April 2024